As it is well known, measuring instruments are essential in understanding the hydraulic performance of hydraulic components and the pressure flow conditions in a hydraulic system. While pressure gauges have been commonly used for measuring pressure for many years due to their low cost and direct readability, they do have limitations. These limitations include poor dynamic performance, inability to record and analyze processes in depth, and imprecise language for information transfer. However, these limitations can be overcome by using recording pressure measuring instruments such as "hydraulic multimeters," which offer higher dynamic performance and objective information transfer.

To illustrate the benefits of using recording gauges, two examples are provided. In the first example, a valve manufactured by Manufacturer B was replaced with a valve manufactured by Manufacturer A. The customer's inspector noticed a difference in performance between the two valves based on the gauge readings. Manufacturer B attempted to solve the problem but failed due to not having access to a logging gauge. The author was then invited to set up pressure sensors and record the pressure conditions of the two valves using a recording gauge. By comparing the test results, it became evident that there were differences in performance between the valves. The test results were shared with Manufacturer B, enabling them to understand the problem and make the necessary improvements to achieve similar performance to Manufacturer A's valve.

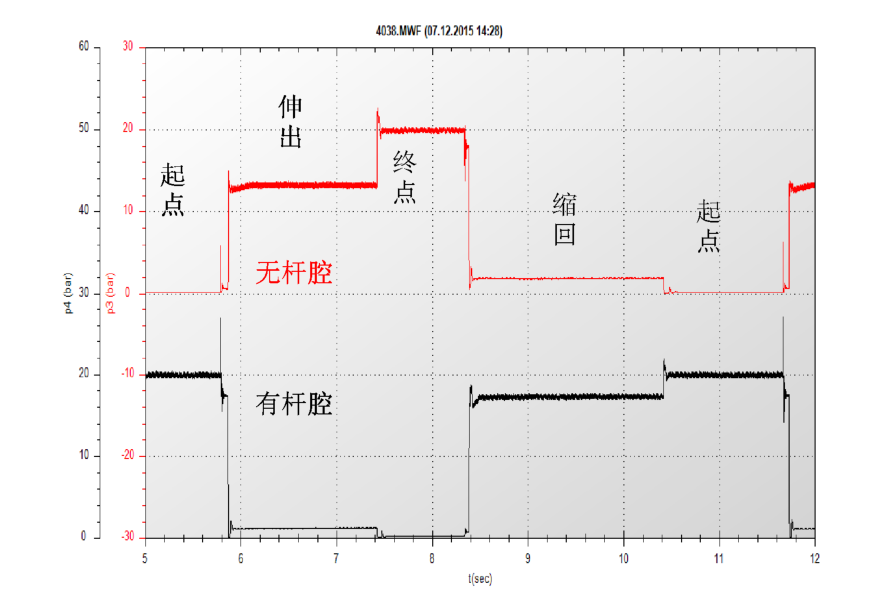

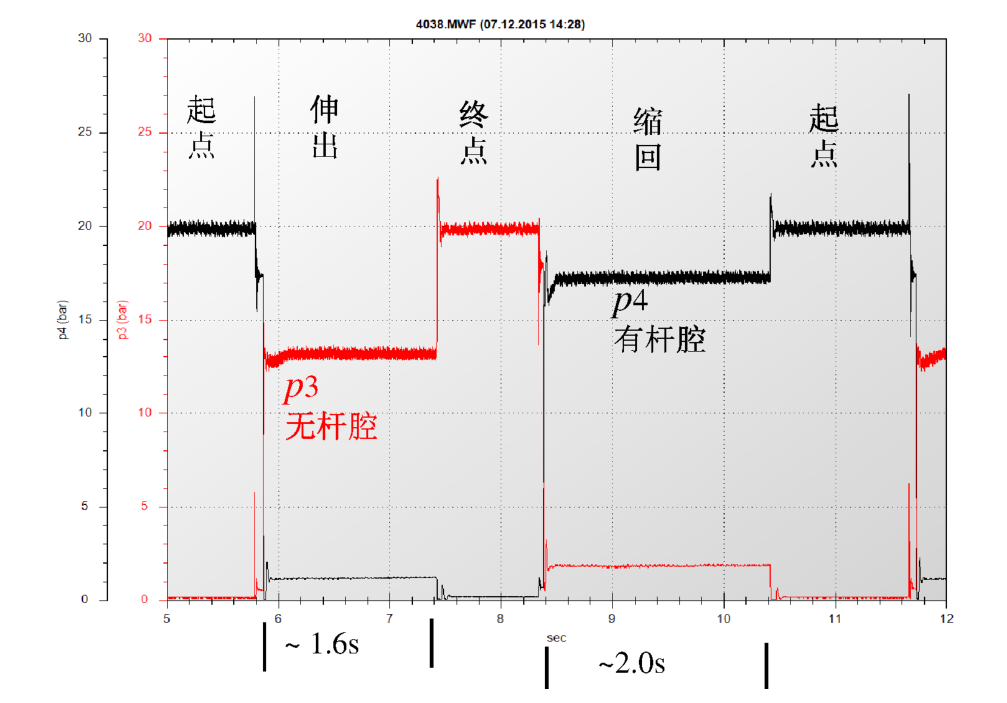

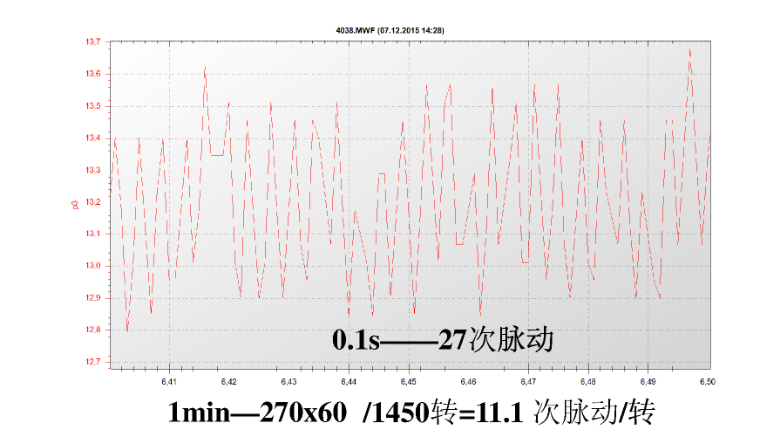

In the second example, two constant-pressure pumps were connected in parallel to supply oil to a hydraulic cylinder. The user expressed concerns about the response time of Pump B compared to Pump A. The author installed a pressure sensor and recorded the pressure changes during the operation of the pumps. By analyzing the recorded data, it was clear that Pump B had a faster response time and maintained a higher pressure than Pump A. This alleviated the user's concerns. The example also highlights how a pressure gauge would not have been able to capture the pressure changes accurately, especially during a specific time period.

The author emphasizes the importance of using recording gauges based on their experience working in German factories and visiting European hydraulic system manufacturers. They believe that the use of recording testers can be seen as a measure of the technical level of hydraulic enterprises. The author suggests that even with the development of electronic technology and the availability of affordable recording testers in the market, simply purchasing the instrument is not sufficient. It is essential to learn how to use the tester effectively to improve technical skills, analyze test results, and let the curves speak for themselves. Starting with simple hydraulic circuits and gradually building expertise and experience is recommended.

In conclusion, the use of recording pressure measuring instruments offers numerous advantages compared to traditional pressure gauges. These instruments provide better dynamic performance, enable in-depth analysis of processes, and facilitate objective information transfer. By learning how to use recording gauges effectively, hydraulic enterprises can improve their technical level and achieve comprehensive and accurate test results.

Pressure compensated flow control valve