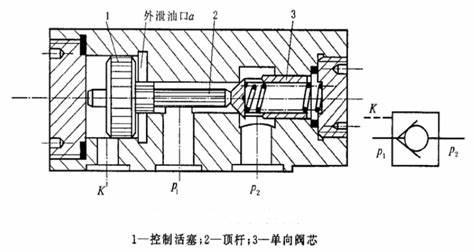

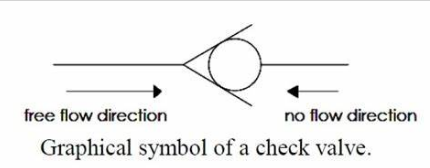

One direction valves, also called check valves or non-return valves, are valves used to prevent the flow of fluids in a specific direction. They are typically installed at the outlet of pumps, pipelines or equipment entrances to prevent fluid backflow. The principle of one direction valves is to allow fluid to flow forward and prevent reverse flow (similar to a diode in a circuit). Depending on the valve core structure, one direction valves can be divided into two types: ball valves and cone valves. Ball valves have a simple structure and are easy to manufacture, but have poor directional sealing and are rarely used; cone valves have strict process requirements but have good sealing and are commonly used in engineering. The working principle of one-way valves can be understood through the following steps:

When one direction valves are completely closed, fluid is blocked on both sides of the valve, forming a static isolation zone. This prevents fluid from flowing between the upstream and downstream of the valve.

When fluid flows from the downstream of one direction valve to the upstream, the one direction valve will automatically open due to the pressure difference of the fluid. At this time, the valve core is under pressure and is pushed away from the valve seat, allowing fluid to pass through.

When fluid flows from the upstream of one direction valves to the downstream, the valve core will automatically close due to the pressure difference of the fluid. At this time, the valve core is acted upon by the upstream pressure and tightly presses against the valve seat, preventing fluid backflow.

Overall, the working principle of one direction valves mainly depends on the pressure difference of the fluid. When fluid flows from the downstream of the one-way valve to the upstream, the valve core will be automatically pushed open due to the pressure difference, allowing fluid to pass through. When fluid flows from the upstream to the downstream, the valve core will be automatically closed due to the same pressure difference, preventing fluid backflow. This automatic switch feature makes one-way valves very practical in various application scenarios, such as preventing gas or liquid from flowing back, and preventing pump reversal.