In the 1990s, it was said that hydraulic technology would be replaced by electric transmission. As a result, the "hydraulic major" and "fluid transmission and control major" that had been set up in dozens of colleges and universities in China were deleted from the "Catalogue of Undergraduate Majors in Ordinary Colleges and Universities" officially promulgated by the Ministry of Education in 1998. Renamed as Institute of Mechatronics. Today, China's hydraulic industry lags behind the world level for 30 years and has become a choke point for our national economy. There is probably no connection between the two.

Why do we have to repeat the old saying here?

In order to reduce the emission of exhaust gas and polluting particles PM10, and protect people's health, there is an increasing call for new energy to replace internal combustion engines. Many countries in the world have formulated a timetable for banning the sale of fuel vehicles. For example, Netherlands, Norway 2025, India 2030, Germany after 2030, France, UK 2040. my country also released the "Technology Roadmap for Energy Saving and New Energy Vehicles" on October 26, 2017.

To provide new energy for mobile devices, there are mainly two modes currently being tested: pure storage battery and fuel cell + storage battery.

Batteries are still too bulky at present, and a car can travel hundreds of kilometers on a single charge, and the battery accounts for more than half of the weight of the car. The energy density of liquid hydrogen is much higher than that of gasoline. Fuel cells can directly convert the chemical energy of fuel (hydrogen or natural gas) into electrical energy, which can greatly reduce the number of batteries carried. internal combustion engine. At present, many companies in the world have launched prototypes of buses and trucks that use the combination of fuel cells and batteries to provide energy.

Compared with cars, many mobile hydraulic equipment require much larger power and consume much more energy. Therefore, the technical difficulty of adopting new energy is also much higher. But I believe that with the large-scale application of new energy, new technologies will be born and costs will be reduced. Therefore, it may be a matter of time before new energy gradually replaces internal combustion engines in mobile hydraulic equipment. This will bring a big reshuffle to mobile hydraulics.

Because, when the internal combustion engine is used as the energy source, although the mechanical energy generated by the internal combustion engine needs to be converted into hydraulic energy through the hydraulic pump to drive the hydraulic cylinder, but to drive the electric drive, it also needs to be generated through a generator. There is an energy conversion, and there is no special advantage in electric drive. And after the battery becomes the energy source, the electric energy is ready-made. Therefore, host designers will give priority to electric drive, and the competition pattern will be unfavorable to hydraulic transmission.

Although hydraulic technology is only a technology that transmits mechanical energy rather than generating mechanical energy, just like the transportation industry, it is only the transfer of goods rather than the manufacture of goods. But just as the transportation industry is not obsolete, the technology to transmit mechanical energy will always be needed.

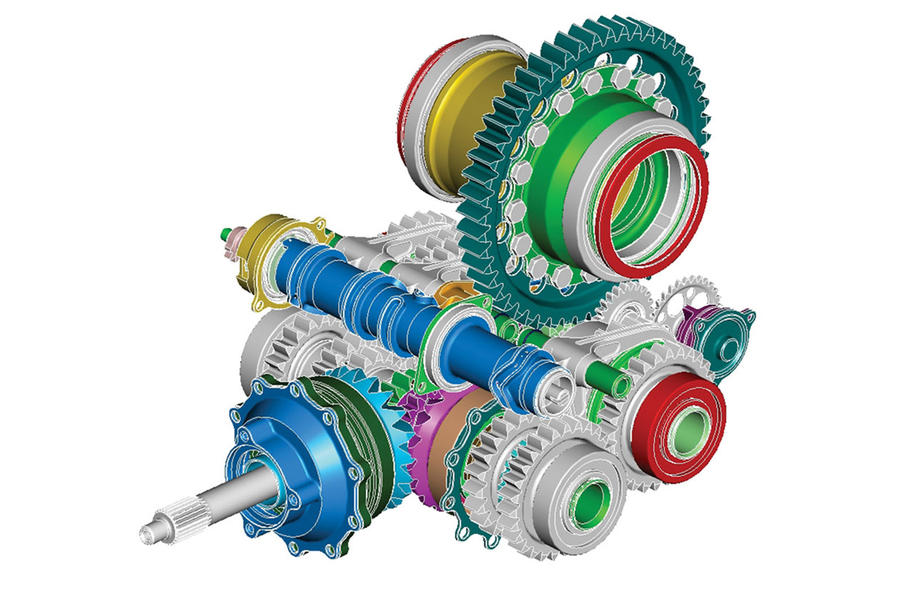

To transmit mechanical energy, in addition to hydraulic pressure, there are also mechanical transmission (lever, gear, belt, chain, etc.), pneumatic transmission and electric transmission (electric motor, electromagnet). Hydraulic transmissions are more flexible than mechanical transmissions and have a much higher force density than pneumatic and electric transmissions, making them the first choice in some applications. This is also like various means of transportation: airplanes, ships, trains, and trucks are all used for transportation, but each has its own characteristics. Although there are competitions in some applications, one will grow and the other will grow, but neither will be completely eliminated.

Example: History shows that new technology does not necessarily replace old technology. The following examples can provide reference.

1) Maglev trains are suspended in the air by magnetic force, and do not touch the ground when traveling, and there is no friction with the ground. In theory, it is extremely beautiful. Its principle was proposed by German engineers as early as 1922. However, it is found to be expensive in actual hands-on manufacturing. Because the magnetic force is inversely proportional to the gap, the straightness of the track is extremely demanding. The world's first maglev train line began commercial operation in 1984 in Birmingham, England, and was dismantled in 2003 and replaced with a wheeled system. Shanghai's maglev demonstration operation line is currently the only high-speed line in commercial operation in the world.

2) For train traction locomotives, steam locomotives were first used (1825), electric locomotives appeared later (about 1840), and diesel locomotives appeared 70 or 80 years later (about 1920). Now, steam locomotives are basically out of use, and diesel locomotives and electric locomotives have been used together for nearly a century. Although electric drive is commonly used in high-speed trains, diesel locomotives are still used in large numbers.

3) The gasoline engine was invented in 1883. The diesel engine was not invented until 9 years later. Over the years, diesel engines have been favored due to their high output, and they have successfully entered the market. They are almost the only power source in ships, trucks, and mobile construction machinery, and they are also equally shared with gasoline engines in cars. Now, however, the future of the diesel engine is in jeopardy as it is a major source of fine particulate PM10 and NOx emissions.

To say that one technology is advanced and can replace another requires a realistic and comprehensive comparison of performance data obtained through actual tests and comparison of various costs. Just comparing one point is not enough. For example, although the servo valve is obviously superior to the electric proportional valve in terms of repeatability and linearity, its application quantity and scope are still far inferior to the electric proportional valve. Not only is the structure of the servo valve complex and the manufacturing cost cannot be reduced, but it is also sensitive to pollution and so on. In addition, for performance, different applications have different focus points. For example, the working durability of hydraulic components is expected to be 20 years for ocean-going ships, but only a few minutes for missiles. What is excellent in one application may be overlooked in another. So, what to say, inventing an artifact that can replace all existing hydraulic technology is not naive. If you don't understand the broad and profound application of hydraulic technology, you are deliberately fooling around. Especially now, some people like to use entertainment advertisements to promote technology, and they can hang up whatever term is fashionable, and there are many hype concepts, such as "air-driven bus" and "water-driven bicycle", completely disregarding the rigor of science and technology sex. Therefore, as a hydraulic technician, it is especially necessary to have the ability and habit of being alert and identifying deception, analyzing the phenomenon more, and thinking about the essence.